On optimizing the sustainability of textile concrete

Considering different types of design, fabrication methods, and materials

This PhD project deals with the sustainability of textile reinforced concrete (TRC) lightweight constructions using the example of different roof structures based on the same footprint. Their sustainability has to be evaluated in a holistic way, taking into account construction and design as well as material and manufacturing methods as well as their dependencies on one another. First, digital design methods are used to compare different types of constructions and designs in terms of their specific requirements on composite components. Depending on the design and the manufacturing methods considered, upper and lower limits of requirements for concretes and textile reinforcements can be defined. Finally, sustainability is assessed through an overview along the entire process chain.

- textile reinforced concrete

- lightweight structures

- sustainability

Context

Despite its high CO2 footprint, concrete as a cast stone is an irreplaceable construction material due to its structural engineering properties. It cannot be replaced in equal scale by CO2-friendlier construction methods and materials such as timber construction. Established sustainability assessments usually evaluate the life cycle of a material, manufacturing process or type of construction in an isolated view. A holistic view of the entire process chain (including resource extraction and waste generation) can lead to completely different assessments. It is common practice to develop more efficient or capable materials in isolated considerations. At the same time, the typical load-bearing structures, in manufacturing as well as in common design models for steel-reinforced concrete, are not meeting the characteristics of TRC nor revealing its potential.

Aims

(1) Further development of effective material components for textile and carbon concrete: Textile fibres do not corrode, in contrast to reinforcing steel. As a result, a thick concrete cover can be dispensed with and thin-walled components with a thickness of only a few millimetres can be produced.

(2) Further development of concrete technology through recyclable concrete mixtures with a low CO2 footprint: Secondary source materials and/or other substitutes will substitute cement.1 By using recycled aggregates or granulated secondary raw materials, the extraction of natural aggregates can be reduced.

(3) Further development of material-saving and material-appropriate design and manufacturing principles: For example, predominantly compressed concrete sections with low bending moments lead to optimal material usage.2

(4) Life cycle assessment with regard to materials, design, and production: The Urban Mining Index by Rosen is leading in the right direction.3 This indicator considers the percentage of secondary or renewable raw materials as well as determines the future recycling potential of different building material components. A logical conclusion from this would be to include manufacturing processes in this assessment in order to map the entire process chain.

Research design

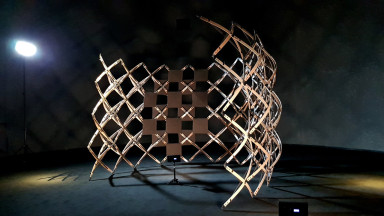

Step 1. Design and construction: In a first step, different design approaches for the roof construction are investigated. Plain and linear structures as well as folded structures and single or multiple curved shell structures are designed and optimized by using the digital design tools Rhino and Grasshopper in comparison and under consideration of architectural aspects. The designs and constructions are optimized according to the criteria in Figure 1, including material requirements, recyclability, etc. Each entails different requirements for manufacturing processes (Step 2a) and materials (Step 2b).

Step 2a. Manufacturing processes: The application of possible manufacturing processes such as wrapping, extruding, casting, spraying, etc. is investigated and evaluated for the construction designs obtained in Step 1. Evaluation includes the degree of prefabrication, manufacturing efforts, process-specific generation of wastes, and both primary and secondary material wastes.

Step 2b. Material: The requirements for the material components of concrete and textile reinforcement are strongly dependent on the prevailing load conditions in the cross-section and on the manufacturing processes used (Step 2a). In addition to strength and durability properties, the workability of the concretes and textiles have an essential role due to their close link with the manufacturing processes (Step 2a).

Step 3. Overall sustainability assessment along the entire process chain: The decisive step in optimizing the sustainability of textile-reinforced concrete takes into account all the preceding results and develops evaluation criteria according to which the results of individual steps are weighted and rated in order to obtain a building structure that is optimized from a holistic point of view on sustainability.

Supervisors:

- Prof. Dr.-Ing. Gesa Kapteina

- Prof. Dr.-Ing. Petra Rucker-Gramm

- Prof. Dr.-Ing. Michael Horstmann